Businesses across various industries rely on small devices to perform key tasks, such as receipt printers and pricing guns in the retail industry, slip printers and pagers in the food industry, and check scanners, EMV issuance machines and currency counters in the financial industry. Because these devices are used so often, it is easy to take them for granted – until one fails.

At the time of break down, few companies understand the range of repair options available to them. They may ultimately accept high repair or replacement costs or even turn towards disposal of their devices rather than repair, leading to increased costs and reduced profitability. In addition, some essential devices can’t afford to be out of commission, reducing a company’s profitability even further.

When devices break down, having a timely and cost-effective repair plan in place becomes critical to avoiding costly downtime.

Who decides the repair path?

When a device fails, businesses typically enlist people such as the business owner, the employee who ordered the device, an internal member of the company’s IT department, or a third-party technician to assess what happened. This person needs to have the knowledge and experience to determine why the device failed, and properly determine repair steps.

This individual can start the repair process in the right or wrong direction. Starting in the wrong direction could lead to increased repair costs, wasting of valuable time, and keeping an essential device out of commission even longer. For example, this individual could spend money replacing parts on a device when it only needed a thorough cleaning. A business must weigh the risk of letting an untrained person work on a device versus the cost of hiring a professional who is trained to perform the repair correctly.

How can small devices be affordably repaired?

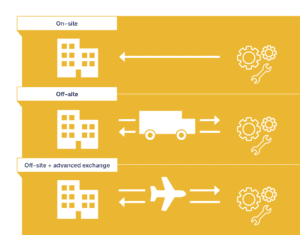

The broad options of what to do when a business device breaks down can be broken down into two main categories:

- Off-site repair

- Off-site repair with advanced exchange

Off-Site Repair

Off-site repair includes the logistical considerations of how the device makes it to the repair shop. There are many options for businesses seeking off-site repair for defective small devices. These options vary widely depending on the repair provider, but may include:

- 3-5-day quick turnaround repair

- 7-10-day basic repair

- Advanced unit exchange

Not all devices can be repaired in a quick turnaround situation. Depot repair distinguishes itself from mailing to a general hardware or “mom and pop” repair shops in a few ways:

- Multiple locations across the country

- Certified technicians performing the required repairs

- Ability to source manufacturer parts quickly

The goal of a depot repair service is to be affordable, convenient, and customizable. Many depot repair services feature ongoing maintenance as a customizable option. These services also have the benefit of working with current warranties or extended warranty programs.

Devices well-suited for depot repair services vary by industry, but some of the most common devices to utilize this method are:

- Payment and transaction equipment

- Monitor, computer, and mobile device screens

- Receipt and slip printers

- Portable scanners and tag machines

When is Advanced Unit Exchange the Best Repair Option?

While a three-day turnaround might not be a disastrous amount of downtime for some less-utilized business equipment, there are many small devices that can’t afford to be out of commission for hours — let alone days.

For these critical devices, there is a repair method known as Advanced Unit Exchange (AUE), sometimes referred to as a “hot swap.” If a business has an AUE agreement, they notify their provider when a device breaks down and the AUE fulfillment provider immediately ships a matching new device on the next business day. When the company receives their new device, they send the broken machine to the AUE provider in the same box that the new device arrived in.

Benefits of AUE:

- Device downtime is dramatically decreased

- Cut down on package waste and shipping costs

- Removes the need for an on-site inventory of spare devices or replacement parts

- Maintains a supplier for new equipment and repairs

- Can be used in B2B arrangements and shipped to a supplier’s customers

Reducing the repair cycle time saves a business money, which is the primary goal of Advanced Unit Exchange.

For business owners, optimizing their small device repair cycle is critical to standing out from the competition, as well as streamlining production and reducing waste. Small device repair solutions that are cost effective and efficient are key performance indicators for inventory and supply chain management, worker efficiency, equipment purchasing, and life cycle management. As outlined above, many factors must be considered when determining the most cost-effective repair option for a business.